Working in complete collaboration to provide offsite manufacturing modular solutions with a high quality finish and attention to detail.

At DPM Contractors we support our clients needs and expectations through a complete collaborative and flexible approach. Over recent years we have recognised the industry need and vision for "offsite manufacture products", and have combined our high end stone finishes expertise with offsite manufacturing of modular pods.

With over 10 years trading experience in our respective fields and markets, we believe that this solution provides a unique offering to our clients by combining offsite manufacturing with the addition of improved quality and attention to detail gained from our relevant experience in delivering high end finishes, ensuring our clients obtain complete confidence in the finished product. This approach also allows us to maximise efficiencies through our supply chain and in collaboration with our exclusive partner, in order to provide improved value for money.

All products are designed and manufactured in the UK providing complete delivery and programme assurance. Our vision is to build long term relationships with our customers and clients to provide exceptional quality services through innovation, advance technology and Modern Methods of Construction. In order to achieve these high standards we have achieved ISO 14001, 45001 and 9001, and CHAS premium.

Pod Structure

The bathroom pods are constructed from 30x30x1.5mm SHS frame with a 12.5mm Fermacell lining

for the walls and 25mm MR MDF ceiling. The floor is also constructed from a steel frame with a

18mm plywood substrate.

The team are currently developing a new lightweight steel frame system which will replace the 30x30 SHS and will reduce site works by providing a wall structure which can be boarded directly to with no additional pattressing, or brackets required.

Pod production & factory capactiy

Our factory consists of 2 production areas & 1 large storage area with easy access for loading articulated lorry’s. Total production capacity is between 50-60 POD’s per week, with a total of 2500 POD’s produced over the past 3 years

Pod Protection

Pods are wrapped using LPS1207 sheeting to protect from fire. Pods will be stropped prior to

dispatch from the factory using certified 2m strops attached to the lifting point at the top of the

pod.

These strops are secured to the side of the pod so they can be easily accessed from people at

ground level on site.

In addition to the above service, we can provide the Clients or main contractors logo to our

protection sheets.

Pod Installation

The pods are sized to be easily & efficiently transported, lifted and installed. Each pod is designed to allow a tolerance gap

around for manoeuvrability during installation and to ensure a perfect finished alignment. The pods can be moved via

telehandler, pump truck or crane. They are then manoeuvred into position by hand.

POD Quality Assurance

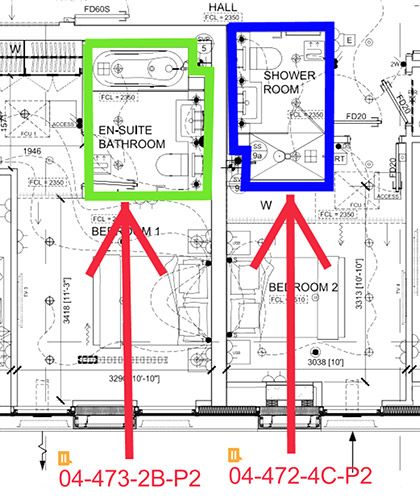

Each bathroom Pod is given its own unique reference, enabling the tracking of the pod throughout the entire production and installation journey.

Offsite testing will be carried out at factory on FieldView system, upon delivery and completion of the PODs copies of all FieldView reports will then be uploaded by our team onto the main contractor FieldView system, or similar as instructed.

The inspection and testing will be in the below sequence;